| Contact Details:

|

10a Brickfield Way

Beaumont Quarter

St Mary’s Bay

Auckland 1010

|

|

+64 9 369 5127

|

| Auckland: |

10a Brickfield Way

Beaumont Quarter

St Mary’s Bay

Auckland 1010

|

|

+64 9 369 5127

|

| Australia: |

6-10 Sunline Drive

Truganina

Victoria 3029

Australia

|

|

+1800 421 781 |

| Sales@spacekraft.com.au |

|

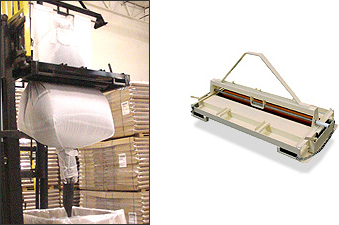

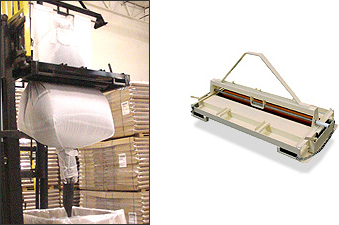

Many equipment manufacturers provide the means to optimize your SpaceKraft packaging line with options that include filling, mixing, and dispensing aids.

Product Name:

Squeeze Roller System

Product Line:

Auxiliary Equipment

Dimensions:

1630mm L x 710mm W

Pallet Size:

n/a

|

Description:

This new SpaceKraft accessory enables producers of hard-to-handle, high viscosity products to ship in a semi-bulk delivery system that allows easy dispensing with virtually no residual product wastage. The system also eliminates the washing and cleanup common when dispensing rigid steel containers with pumps and follower plates, since the empty squeeze bag's polyethylene liner is easily removed for disposal or recycling.

Benefits:

* Ideal for highly viscous products

* Easy dispensing with virtually no residual product wastage

* Eliminate cleaning rigid steel containers

* Empty squeeze bag's polyethylene liner is easily removed for disposal or recycling

|

|

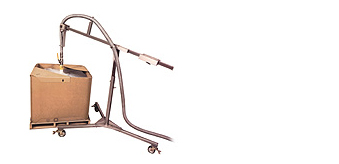

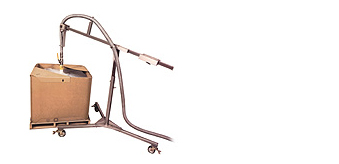

Product Name:

Articulating Arm Filler

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

The Articulating Arm Filler includes a three-legged mast and boom that support a hose and valve assemble. Simply attach one end of the hose to the filling line and the other to the inner poly bag. Open the valves, and filling is automatic until they're closed. The filler is equipped with a counterweight on the rear of the boom, allowing the arm to rise as the product fills without impacting weight. Increased production speed, because the operator is free to set up the next box and close the one just filled.

Benefits:

* Reduce labor

* Increase production speed

* Holds the filling tube in place, freeing up the operator for other tasks

|

|

Product Name:

Ball Valve Assembly

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

A special SpaceKraft cutting tool is provided in order to puncture the bag for side dispensing. Designed to work with any standard 2 or 3" valve, it features a serrated retractable shaft. This is inserted through the open valve and nipple to puncture the plastic bag. When the bag has been punctured, the valve closed and the cutting tool removed, product can be dispense either by pump (quick disconnect recommended) or gravity method (90 degree elbow recommended).

Benefits:

n/a |

|

Product Name:

Buttress System

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

Prevents cross threading.

Benefits:

n/a |

|

Product Name:

Dispensing Wands

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

n/a

Benefits:

n/a |

|

Product Name:

SpaceKraft Tilt Table

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

n/a

Benefits:

n/a |

|

Product Name:

Snouted Bag and Jig

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

For those who need greater access than a standard 2" fitting.

Benefits:

* Ideal for products with ingedients being added later

|

|

Product Name:

Hanging Bag and Jig

Product Line:

Auxiliary Equipment

Dimensions:

n/a

Pallet Size:

n/a

|

Description:

n/a

Benefits:

*

Aseptic filling

* Automatic filling

* Hose length limitations

|

|

|